Die casting in zinc

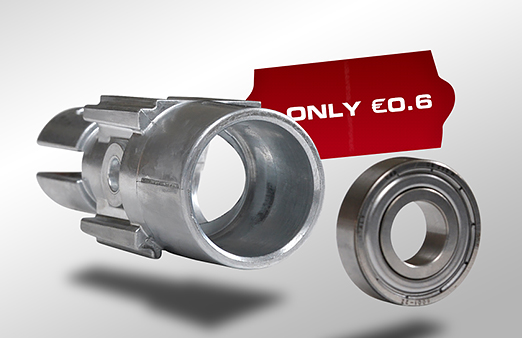

Die casting is a manufacturing method that is used for a variety of materials. Parts can be die cast in zinc, aluminium or magnesium. Gjuteriteknik specialises in die casting zinc, however. As a manufacturing method, die casting is similar to injection moulding for plastic. Just like injection moulding we use a mould and inject the material into it. But in die casting it is molten metal that is injected into the mould.

Cost-effective method

he method is well developed and allows parts to be produced very efficiently, at high speed and to precise dimensions and tolerances. Die casting is therefore well suited to the production of large volumes. Products with complicated geometries can be manufactured cost-effectively with die casting.

Zinc in everyday use

Zinc is a material that is used in many everyday products, although we may not always realise they are made of zinc. Typical products can include door handles in cars, the shaft of a razor or the star at the front of a Mercedes. Zinc can in principle be used anywhere we require a product to have the character or hardness of metal, long life or specific properties. In the electronics industry, zinc is often used for enclosures and casings, to take advantage of zinc’s protective and shielding properties.

Pimping zinc parts

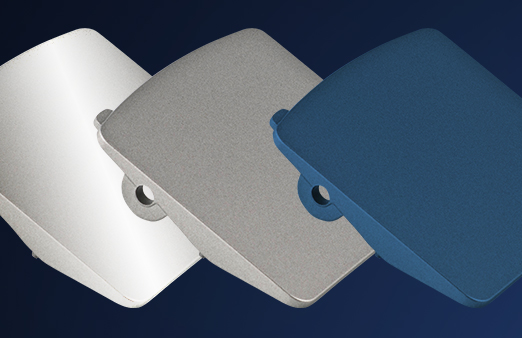

Zinc is matt grey in its natural state. Raw zinc is commonly used for parts that sit inside an enclosure or in locations where its appearance is not so important. But if a part will be seen more often, it may be desirable to give it a different finish. Different surface treatments give different appearances. The only limit is your imagination.

Respect for the environment

At Gjuteriteknik, production is based on fully automated processes. No material is wasted here. All surplus material is re-used and made into new products. Zinc has a low melting point. This gives it an advantage over aluminium, for example. Energy consumption is lower. Production is still an energy-intensive process, however. To safeguard a clean supply of energy, Gjuteriteknik has invested in wind power, and today our plant is entirely supplied with electricity from wind turbines.

Like to know more about the advantages of die casting in zinc? Click here!